Our Technology

This section aims to provide a general overview of the Fumiable manufacturing process. It shall not be construed as a complete technical disclosure, proprietary specification, or license to reproduce, manufacture, or modify any part of the described technology.All process details, schematics, and design know-how remain the exclusive intellectual property of KYCZ Pte. Ltd. (Singapore) and its authorized affiliates. If you have any questions about this process, or require further clarification, please contact us at [email protected].The content presented herein is proprietary and must not be downloaded, reproduced, distributed, or adapted in any form without the prior written consent of KYCZ Pte. Ltd.

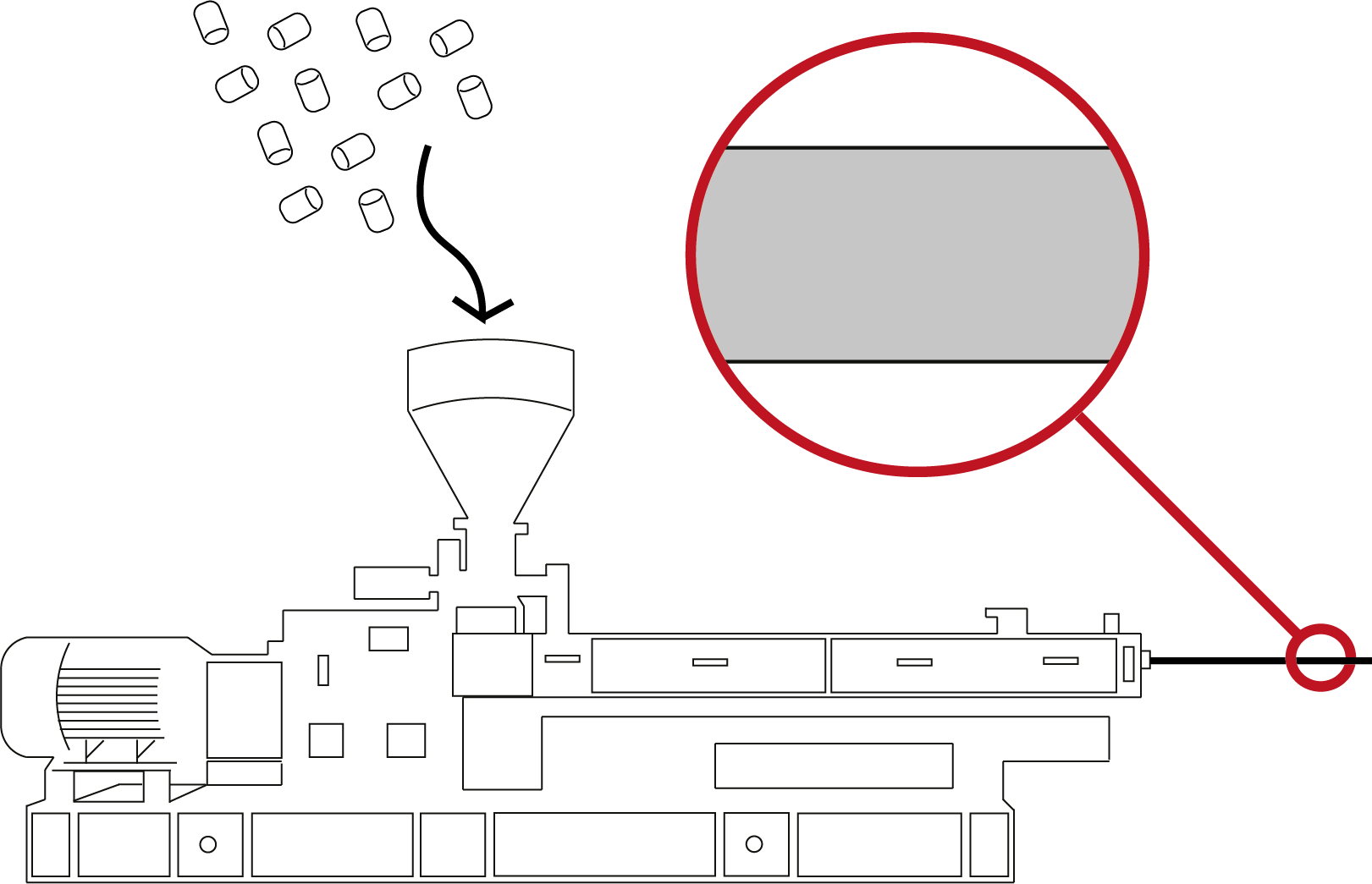

Step 1 - Polymer melting and extrusionPolypropylene pellets (and other additives) are melted and extruded through a flat die to form a thin, continuous film that will later be converted into tapes.Why Polypropylene?Polypropylene was chosen for Fumiable because it combines tensile strength, versatility, global availability, proven food-contact safety, and 100% recyclability.

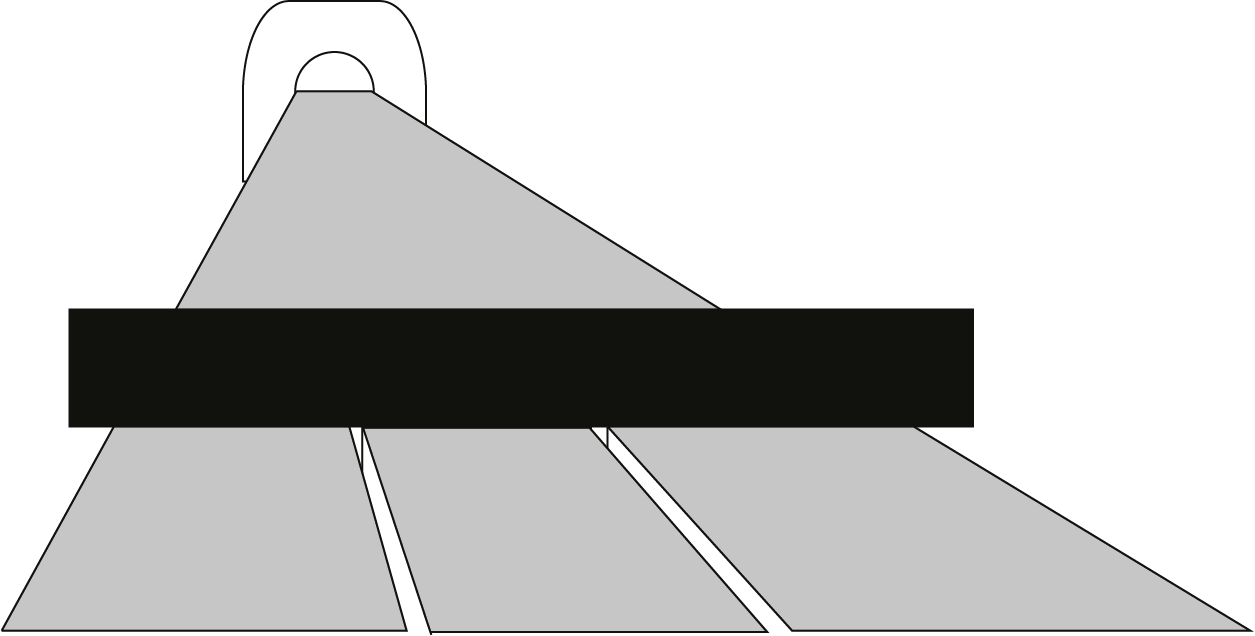

Step 2 - Tape SlittingThe sheet passes through precision knives that slice it into narrow plastic tapes.

Next, the tape enters a splitting machine designed to restructure them into a webbed lattice.This is achieved through micro-incisions or tension-guided stretch slits along the surface.

As the tape is pulled under calibrated tension, the machine performs longitudinal micro-splits, expanding the tape into a net-like or webbed structure while preserving tensile strength.This modification reduces the material’s density, enhances breathability, and improves grip during the yarn-forming stage.

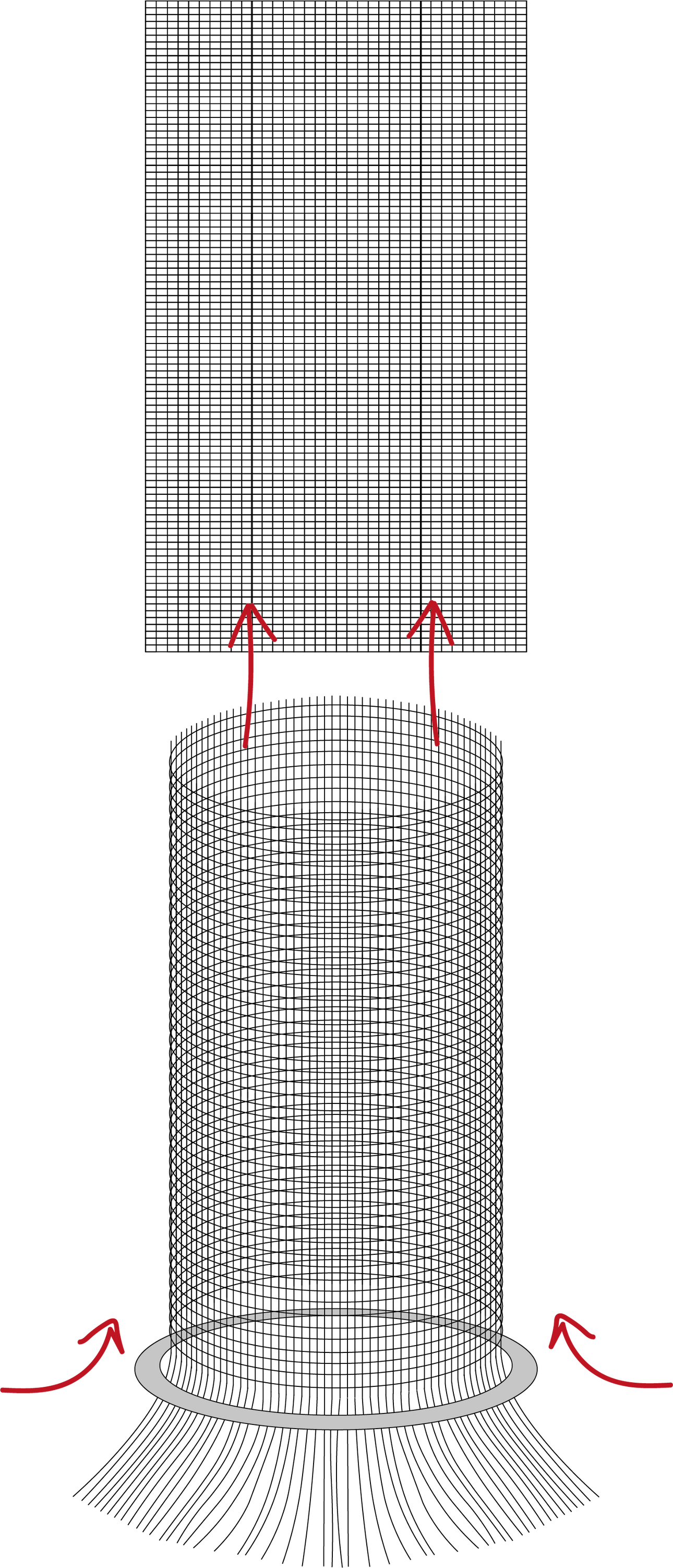

Step 3 - Yarn formation via twistingThe stretched tapes are twisted into yarns on a spinning axis. This twisting process imparts strength and consistency to the material.

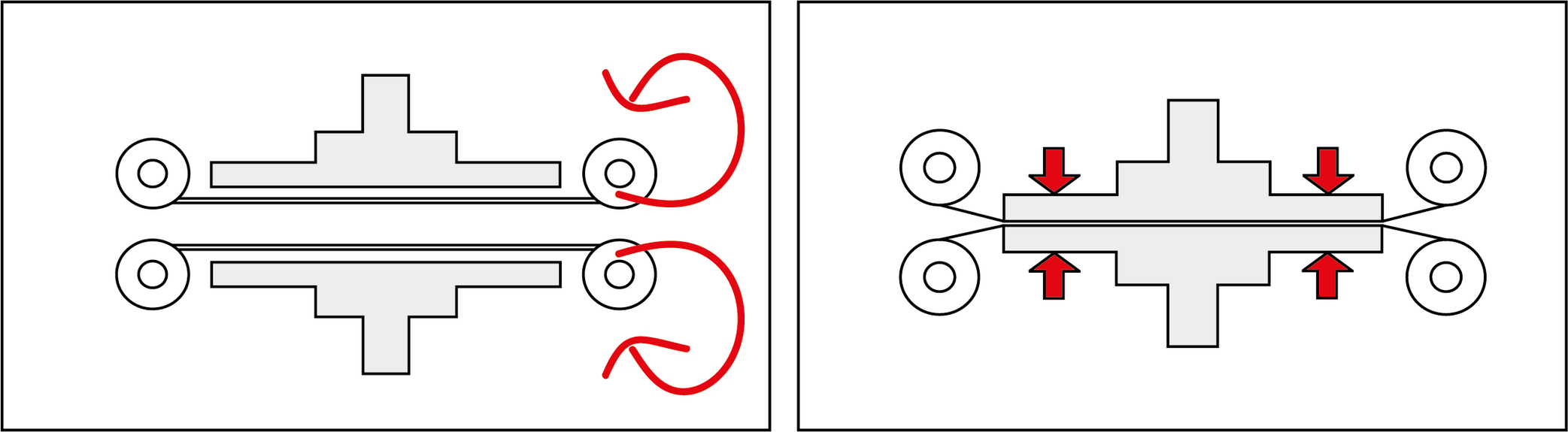

Step 4 - Circular WeavingYarns are loaded into a circular loom, producing a continuous tubular fabric. The weave count and interlacing pattern are determined at this stage.Step 5 - Fabric FlatteningOnce the tubular woven fabric is formed on the circular loom, it undergoes a flattening process to transition it from a cylindrical shape into a dual-layered planar form.This is achieved using a series of synchronized rollers that compress the tube along its vertical axis, folding it symmetrically into a flat sheet for subsequent processes.

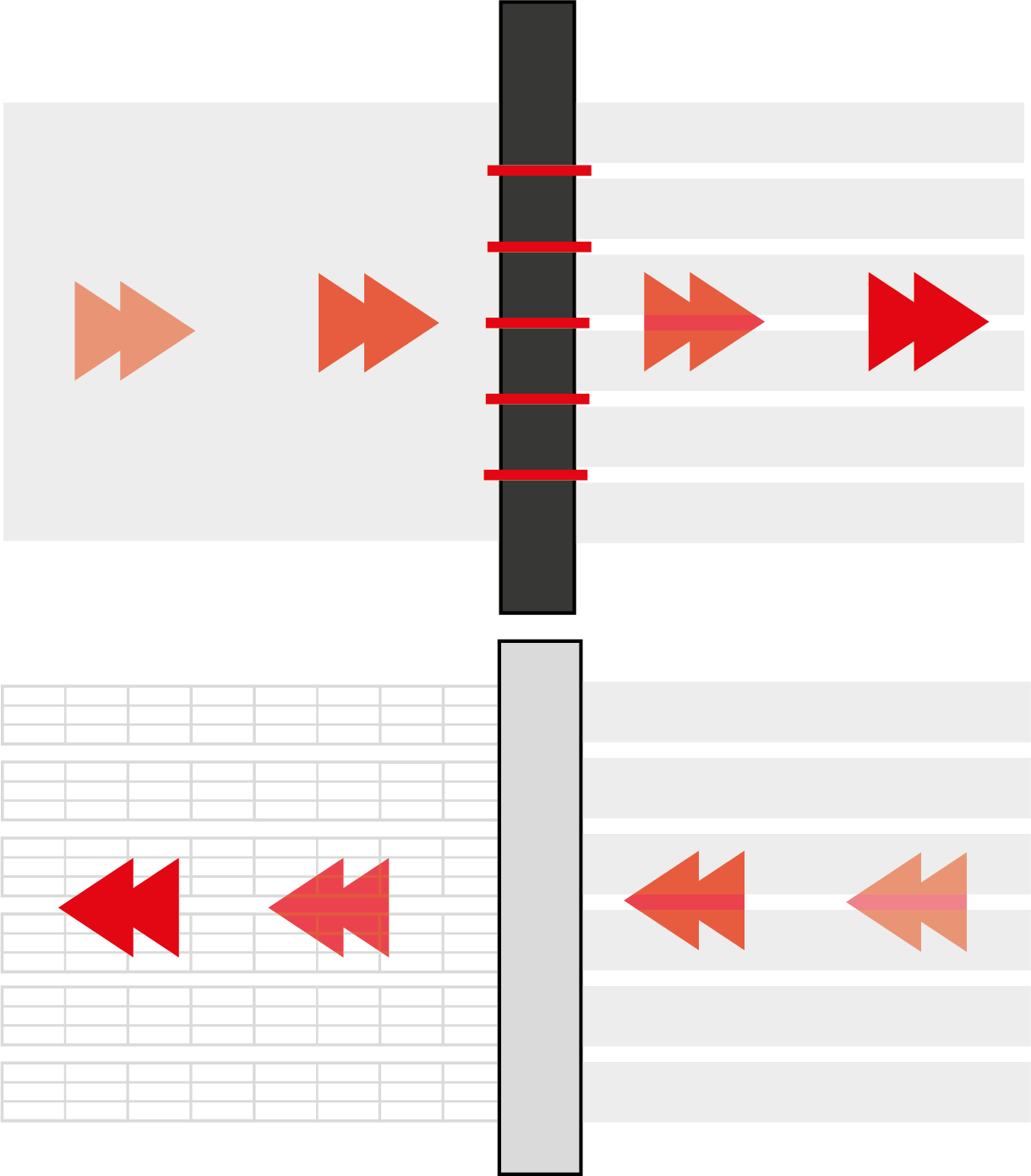

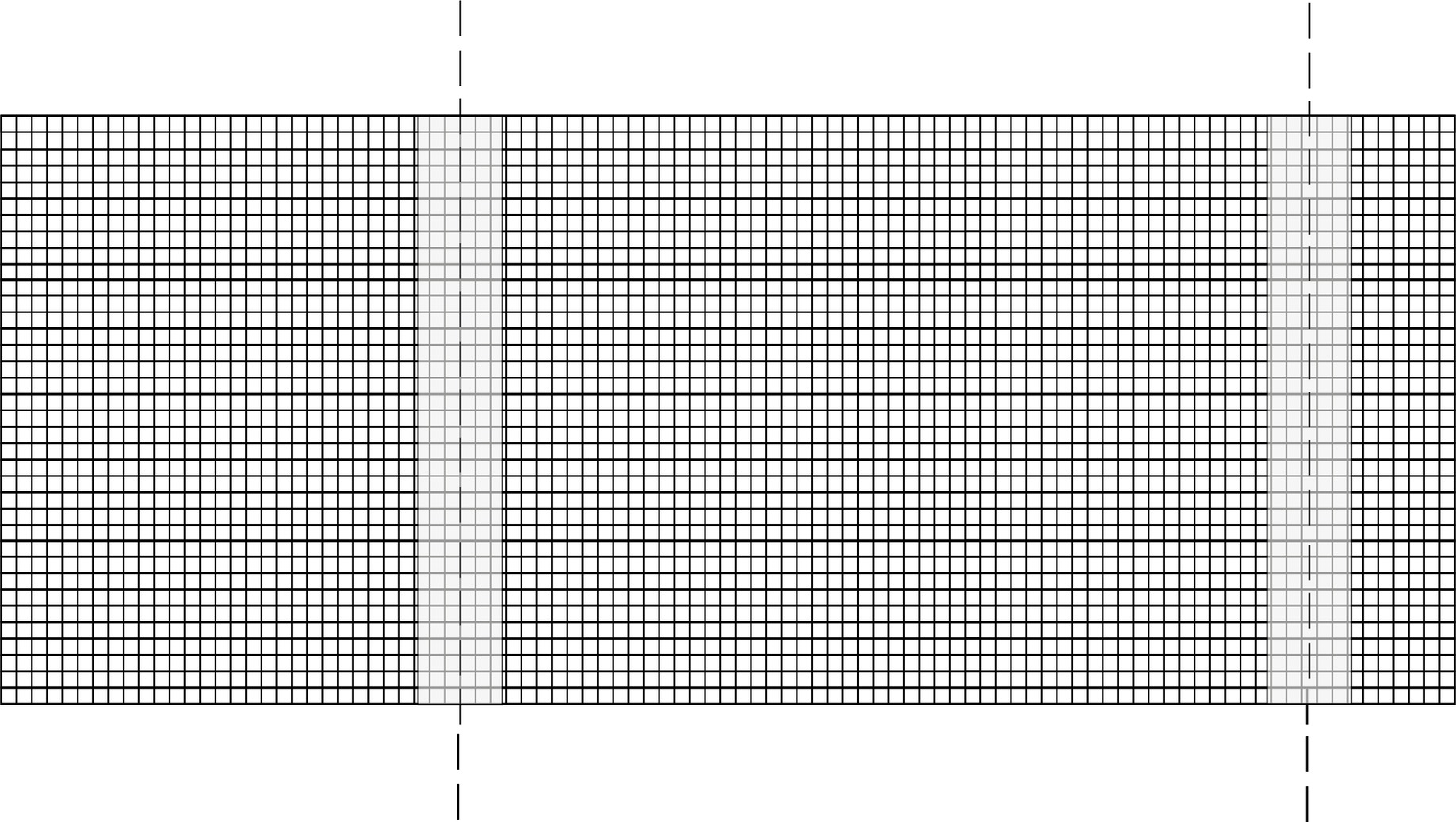

Step 6 - Lamination and SealingTwo polypropylene sealing films - P1 (top) and P2 (bottom) - are heat-welded at a fixed width (typically 49” or other suitable length of the bag) along the flattened fabric. This precise film welding is the most critical structural identifier of the Fumiable PP Jute Bag, preventing fraying and ensuring structural integrity.

The laminated fabric is passed through a heated roller press. Uniform compression ensures wrinkle-free bonding and dimensional stability - a crucial step before the bag cutting process.That lamination is the critical innovation that prevents fraying, strengthens the edge for sewing, and locks structural integrity into the fabric.This ensures that every Fumiable bag survives handling stress better without compromising breathability.

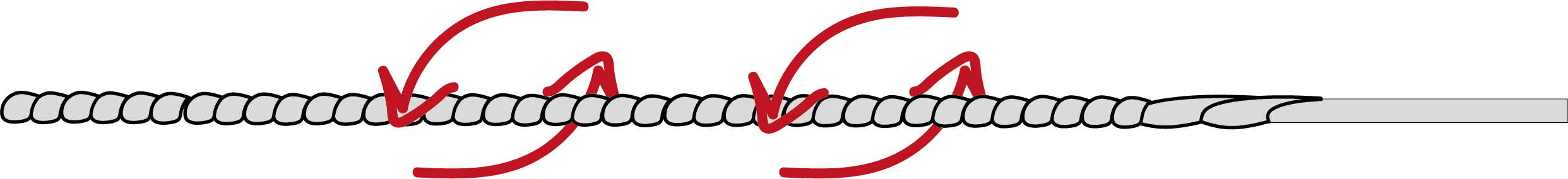

Step 7 - Cutting to Bag SizeThe continuous fabric roll is then cut into individual sheets based on the required bag dimensions.Step 8 - Bottom Folding and StitchingEach cut piece is folded and double-stitched at the bottom to form a bag. This reinforces the base for load-bearing capacity.

Final Step - Final Bag OutputThe final product is a structurally robust, recyclable PP Jute Bag - ideal for fumigation, ventilation, and sustainable commodity transport.Key FeaturesBreathable, best-in-class permeability

Mold-resistant yarn (Pathoglaze models only)

Null Gap digital verification for weight and traceability

Rugged durability for export handling

100% recyclable mono-material construction

Illustration DisclaimerAll graphics and product images shown are for illustration purposes only. Actual product appearance, weave pattern, color tone, and material texture may vary depending on manufacturing batch, tooling, and lighting conditions.Fumiable® and its affiliated companies reserve the right to modify designs, specifications, or visual elements without prior notice as part of ongoing product refinement.

About Fumiable®

Product / Resources

Connecting with us

© 2025 KYCZ Pte. Ltd. All rights reserved.

“Fumiable,” the stylized “f” emblem, and associated designs are registered trademarks of KYCZ Pte. Ltd., Singapore.

The information contained herein is accurate at the time of publication but may be amended, updated, or withdrawn without prior notice.

Unauthorized reproduction, imitation, or use in any form constitutes an infringement of intellectual property rights and may result in legal action.